Recondition Your Centrifuges!

Centrifuges operate using high speeds and expose great strains. However, wear and tear is inevitable and cannot be avoided. We at Huning, offermaintenance and repair service for all centrifuge types. Our service team comprise of experienced technicians, who have worked professionally for many years. Spare rotors of all renowned manufacturers are availableat your convenience. Restoration and gaining acceptance of accident prevention regulations are our main strength.

Our service: Dismantling and assembling, balancing and reconditioning

Protection of wear and tear

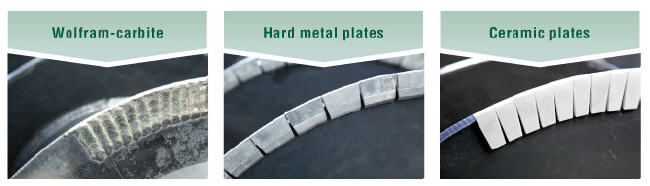

The bowl rotating assembly must comply with our high standards, in order to achieve best dewatering benefits for a longer period of time. That is why we offer a variety of possibilities, to protect the scroll from excessive wear.

Gearbox Service/Maintenance

For The core of your facilities: Speed variable drives have often been neglected during maintenance. We however, dismantle and clean the drives. Furthermore we only replace spare parts where needed, saving you any unnecessary repair charges.

Our service:

|

Belt filter press: Recondition into new ones!

Belt filter presses cause less wear and tear and are easy to maintain machines. As a general rule, these machines operate with fewer breakdowns. Our regular servicing may help to eliminate the risk of breakdowns. After an extensive amount of use, we recommend a complete revision of the belt filter press. Once serviced, your machine will be as good as new.

The result: an operationfree of defects with better dewatering results.

|

|

Camera inspection in centrifuges.

Some machines may appear to be in good shape on the outside, but what does it actually look like inside? Thanks to our specialist cameras, we can identify whether a machine is equally working well on the inside. This inspection would be conducted regularly.

Your benefit: you will only experience a timely and efficient dismantling. You will also know when the repair has to take place and how much repair is sufficient.

|

|

Balancing: Avoid time-consuming dismantling.

With the assembly of rotating parts new unbalances could arise in the entire rotor. Using high vibration power together with our mobile balance device, we have the ability to build your machine in its mounted condition. This means you will be saving the additional expense of a dismantling job.

|

|

Checking bearings: making sure everything runs smoothly.

When checking bearings, we do not need to dismantle the rotating assembly for measuring temperature and vibrations bowl curve. Using the curve measurements this is checked against the vibration condition of the bearing. These measurements should be regularly conducted, to avoid any damages to the bearing

|

|

Spare Rotors: A perfect fit!

We have a whole range of spare rotors available. Should your machine break down or if it is in repair, we would behappy to provide you with a replacement rotor. In case we could not offer you the appropriate rotor model, you can receive our mobile unit at your convenience.

|