High-class centrifuges

(Sludge dewatering, separation and preparation)

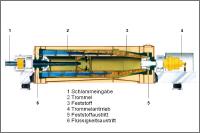

Huning Umweltechnik uses high quality centrifuges for dewatering of municipal and industrial sludge. The processes

and procedures of dewatering, thickening, concentrating and conditioning are carried out by use of mobile, semi-mobile or stationary systems. The centrifuges operate in compliance with the 2-phase schematic, as a rule with reverse flow drives. In this system the solid parts and particles are separated quickly and effectively from the liquid phase due to the large centrifugal force. The centrifuge causes that the solids can depose on the drum wall, whereas the separated liquid phase can leak on the reverse other side.

The result is a large gain of dewatered sludge which is almost a solid free liquid.

The separation level of solid depends on different factors. The variable rotating speed and the size of centrifuges ( length and diameter) are an important issue. For organic sludge an addition of polymers is vital. Our field service engineers adjust the degree of metering, point in time of addition and the certain polymer type closely to your needs.

The dewatering systems offered by Huning have stood the test for years. We provide throughput rates from 10 to 200 cbm/h.

Please find more information on the following pages:

| Mobile centrifuges | Semi-mobile centrifuges | Stationary centrifuges |

|

|

|